Case Study: Streamline Transportation Management

A leading provider of beverages and food products headquartered in the Southeast offers a broad portfolio of beverages including water, soda, sports drinks and more. Known for their innovation and growth, the company manages more than 1,000 beverage SKUs and manufactures nearly a billion units each year.

Seasonal demand and a complex supply chain have made their operations uniquely dynamic. The bottling industry is highly sensitive to seasonality, with demand peaking during the summer months from Memorial Day to Labor Day, referred to as “100 days of summer.” Major holidays and weather patterns further influence demand, requiring a responsive and adaptive supply chain strategy.

Initial Challenges

A long-time Penske Truck Leasing customer, the bottler initially leased hundreds of vehicles from Penske for their transportation needs. To enable scale during peak seasons, many drivers were leased or temporary. When the company began to experience a high driver accident rate that resulted in costly product losses and safety risks, they turned to Penske Logistics for solutions.

Transportation Management

The bottler was in need of reducing risk for their fleet operations but were concerned about maintaining the high level of service to their customers if they outsourced their transportation to Dedicated Contract Carriage (DCC). Penske Logistics performed an operational assessment to evaluate their operations and proposed a solution to outsource a complicated portion of their transportation between manufacturing and the distribution center. The bottler opted to maintain transportation from distribution centers to their customers at retail stores.

Penske Logistics converted their private fleet to DCC for routes into distribution centers, reducing accidents and ensuring safer, more reliable deliveries.

Additionally, the peak weeks required a significant increase in trucking capacity, nearly double the normal volume. Recognizing these challenges, Penske implemented solutions to improve fleet utilization and transportation efficiency, reduce risks and implement technology to improve planning and forecasting.

Penske’s agile approach ensures scalability, deploying additional trucks and drivers to meet demand while maintaining seamless operations during off-peak periods.

Managing Seasonal Fluctuations

Before partnering with Penske Logistics, the bottler utilized a broker model to meet demand during peak seasons. This method led to unpredictable costs as there was a lack of load visibility, contracted rates, on-time deliveries and oversight beforehand.

The bottler found that a multi-service model like Penske Logistics — which combines truck leasing and maintenance for final-mile deliveries fleet, dedicated contract carriage to efficiently handle their complex delivery network and freight management (FM) for overflow — would allow the bottler to flex as needed during high-demand periods, ensuring uninterrupted movement of goods.

Utilizing support from Penske Logistics’ vast and reliable carrier network, the bottler found flexibility and cost savings, reduced exposure to volatile spot market rates, and other benefits, and was even able to upgrade their franchises to regional hubs when the company began experiencing exponential growth.

Penske’s tailored solutions and commitment to excellence have been instrumental in supporting their continued success.

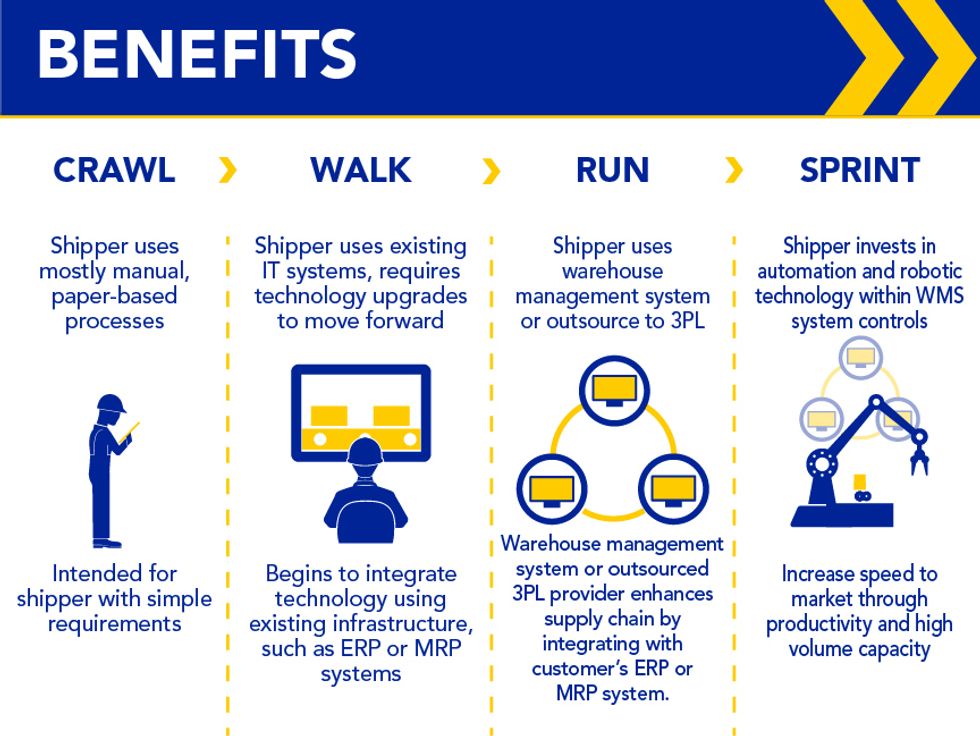

Customized Technological Integration

Beverage retail is a highly competitive industry with more choices for consumers than ever before and counting. The bottler realized that they needed to improve their technology systems to operate efficiently and gain a competitive advantage. They struggled with implementation, managing yard operations, monitoring KPIs and tracking transportation spend. The bottler’s preference for tailored solutions led Penske Logistics to implement technologies and develop custom dashboards for more operational visibility.

Dock Scheduler

Transitioning from a manual whiteboard system to a dock scheduler provided real-time updates, streamlining operations across 10 franchise locations and outside carriers.

KPI Dashboard

Penske Logistics developed a Business Intelligence dashboard for the bottler, enabling them to track key performance indicators and make data-driven decisions. The bottler’s core operating team at Penske Logistics analyzes this data in weekly roundtables and monthly reviews.

Financial Reporting

Penske Logistics also developed an annual business forecast, submitting a detailed budget each November to guide financial planning. Monthly reviews are held to compare actual versus projected expenses across billing groups, ensuring cost transparency and identifying key financial impacts.

Geographic Cost Tracking

Monitoring cost-per-case metrics across 200 business segments provides precise costs to determine pricing. These advancements have improved efficiency and aligned operations with the bottler’s business goals, such as portfolio diversification and enhanced value.

Measurable Impact

Since the inception of this partnership, the bottler has experienced substantial growth, scaling from 25 drivers to 135 and covering over 11 million miles annually. Penske’s ability to flex resources during peak periods has driven efficiency and cost savings, supporting the bottler’s growth and diversification goals. By shifting from reactive brokerage systems to proactive, integrated solutions, Penske has reduced risks, improved safety and optimized costs, leading to a measurable impact on the bottler’s operations.

Looking Ahead

With a shared focus on innovation, growth and value, the partnership exemplifies how tailored logistics solutions can drive success in even the most complex industries.

As the bottler continues to diversify its portfolio and expand its reach, Penske remains a steadfast partner, offering strategic guidance and operational excellence. The trust and collaboration between Penske and the bottler are cornerstones of their long-term success, which led to a recently renewed five-year contract.

To learn how Penske can help your business achieve its goals, contact us.